In modern manufacturing, stainless steel, thanks to its exceptional strength, corrosion resistance, and aesthetics, is widely used in medical devices, automation equipment, electronics, food processing machinery, and automotive parts.

However, for processors, it presents a significant challenge: high strength, low thermal conductivity, easy knife sticking, and deformation.

We are experts in resolving these challenges.

Our Advantages - Professional Stainless Steel CNC Machining Capabilities

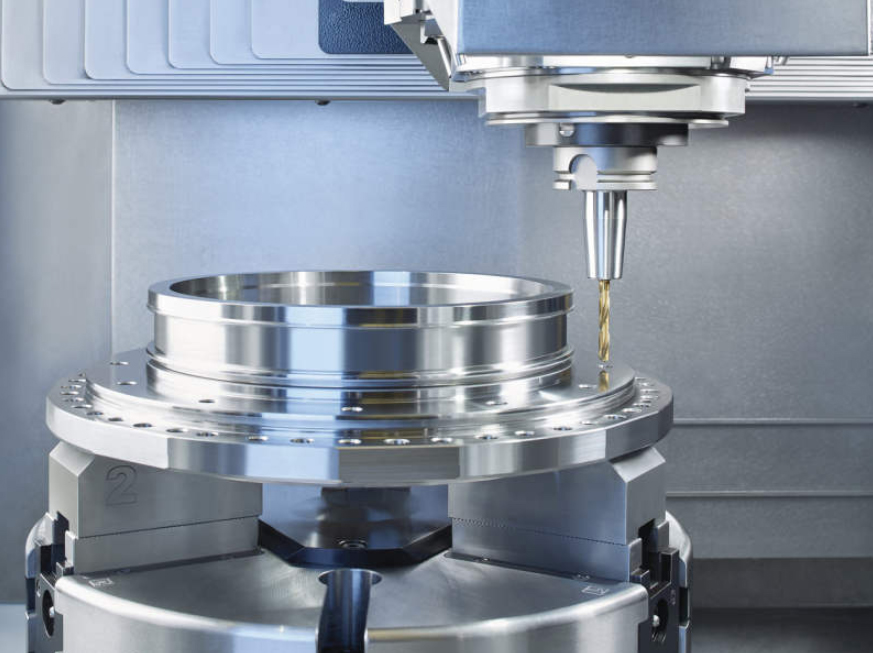

High-Precision Equipment Support

Equipped with multiple high-rigidity three-, four-, and five-axis CNC machining centers with spindle speeds up to 20,000 rpm, we can meet machining needs ranging from complex cavities to precision shafts.

Experienced Team of Technicians

With over 10 years of experience in stainless steel parts machining, we are familiar with the cutting characteristics and heat treatment protocols for various grades, including 304, 316L, 410, 420, and 17-4PH.

Perfect Surface and Dimensional Control

Through optimized tool paths and cooling control, we achieve surface roughness of Ra 0.4–0.8μm, and dimensional tolerances within ±0.005mm.

Efficient Inspection and Quality Assurance

We utilize coordinate measuring machines (CMMs), projectors, and hardness testing throughout the entire process to ensure that every part meets customer standards and assembly accuracy requirements.

One-Stop Processing Services

From raw material procurement → programming and design → CNC machining → polishing and deburring → surface treatment (passivation, electrolytic polishing) → testing → packaging and shipping, we provide a truly one-stop stainless steel parts manufacturing solution.

We support:

Single-piece prototyping

Small-batch trial production

Volume OEM/ODM customization